G.G.B.S.

Ground Granulated Blast-Furnace Slag

What Is GGBS ?

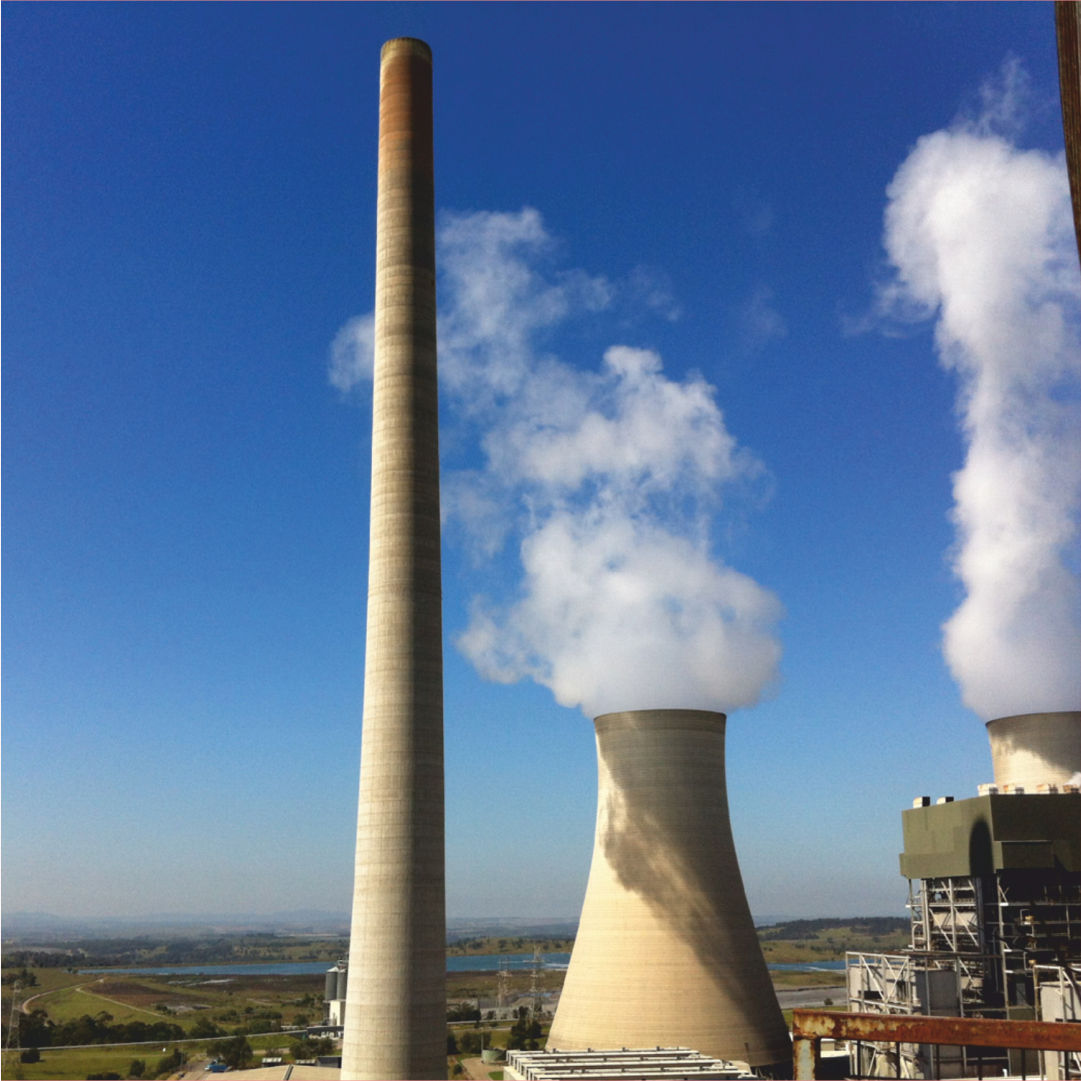

GROUND GRANULATED BLAST FURNACE SLAG (GGBS OR GGBFS) Is an Environmentally Friendly Product And Made From A By-Product Of Iron Manufacturing. Ground-Granulated Blast Furnace Slag Is Highly Cementitious And High In Calcium Silicate Hydrates (CSH) Which Is A Strength Enhancing Compound Which Improves The Strength, Durability And Appearance Of The Concrete. Harikrishna Groups Introducing New Green Building Product Known as Ground Granulated Blast Furnace Slag (GGBS / GGBFS).